The engine is one of the main components of the car, and the cylinder head is the heart of this component. We will tell you about the methods of grinding, the reasons, preparatory work and the process.

The content of the article:

- Causes

- Grinding options

- Preparatory work

- Grinding process

- Price

Engine breakdown is not one of the pleasant situations, and bent cylinder head is often the cause of breakdown. In this case, the first question is how to grind the cylinder head, since it is she who is responsible for the quality of the engine. What is a cylinder head? From itself, it is a cover that covers the cylinders and, as standard, is attached to the block with studs and bolts.

In the cylinder head, everything is interconnected, if one part fails, then it pulls the rest along with it. Thus, it is worth looking after the engine as best as possible and making repairs on time. As for grinding, every time it breaks down, it should not be carried out, but only if irregularities appear.

Top reasons for sanding

The first and main condition for starting grinding is the uneven installation of the cylinder head gasket and its subsequent burnout. The reasons for this can be engine overheating, the ingress of small mechanical parts or water, which, when detonated, can damage the gasket.

The gasket itself is not so simple, it consists of several layers and a frame, it is made from perforated sheet steel. The main purpose is to seal the joints of the two parts. Boiling the engine, bubbles in the cooling system, changing the color of the oil are the first indicators that the cylinder head gasket has become unusable.

Engine tuning is often considered the second reason for grinding. A sign for this is a decrease in engine power when you press the accelerator pedal, or simply the engine stops pulling. I want to say right away that the process is not easy and will require both time and money.

Cylinder head grinding options

Grinding the cylinder head is a delicate and time-consuming process. The best grinding is carried out in service centers at service stations, but as an option, you can do it at home. Special devices and fixtures are very expensive. If we take remote settlements, then it is not always possible to find a simple service station.

In fact, it can be divided into manual and mechanical grinding. Mechanical is performed on special machines. Manual cylinder head grinding, although a longer procedure, requires a lot of patience and perseverance.

Preparing for sanding

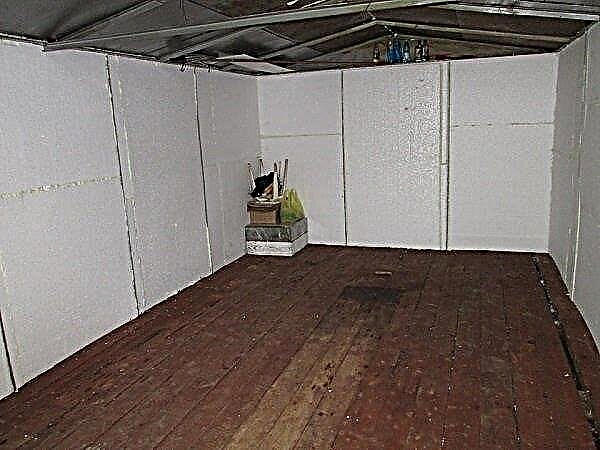

For self-grinding, we first need a set of probes, a curved metal ruler, with its help we will determine how much the cylinder head is bent and the degree of its roughness. This is more likely a method by eye, since only visually it is possible to understand where and how much it costs to grind. In addition to such irregularities, there may also be cracks and similar defects. This suggests that the engine overheated well and detonated. To identify such cracks, it is worth painting the cylinder head with slowly drying paint and wiping it off after a few minutes. Where the paint remains and there will be a crack. It is desirable to use paint in bright colors. Unfortunately, it will be possible to see only large cracks, but microcracks only with the help of special devices.

In any case, no matter how bent the cylinder head is, the first thing before starting grinding is to check for both large and micro cracks.

Cylinder head grinding process

Removing the cylinder head is different for each car and it makes no sense to describe it. But it is worthwhile to understand that for this you will need to drain the oil, coolant, remove everything that interferes, well, and stock up on new consumables.

Having removed the cylinder head, there are many questions about how much it costs to grind it, how to do it and how to check the result. But everything is not as scary as it seems at first glance. When grinding, it will not be superfluous to check the valves and replace the valve seals. This is done so that after collection it is not necessary to grind the burnt-out valve.

To start grinding, we need a whetstone or the like to remove uneven layers evenly, accurately and without bends. Next, it is worth taking a piece of glass according to the size of the cylinder head and a little diesel fuel, since it does not dry out quickly. After a little sanding, wipe the entire surface of the cylinder head with diesel fuel with a thin layer and apply clean and dry glass. It will immediately show where there is still a gap, and where they went too far with the process.

In places where they have gone too far, a circle will form, with air at the edges, and where they have not been sanded, on the contrary, a circle of air and fuel around the edges. Next, remove the glass, wipe the cylinder head dry and repeat the grinding process with a stone.

It is worth knowing that when grinding the cylinder head, the movements of the grinding stone should be smooth in the form of zero or eight, but not straight and sharp. The result should be a mirror-like and completely flat surface, after which you can safely install and assemble the engine.

Cylinder head grinding price

To a large extent, the cost of such a procedure will depend on the chosen method and engine brand. It is worth remembering that the more expensive the car and the larger the engine, the more expensive the procedure will be.

On a special machine, such a procedure will cost from 800 rubles per cylinder, manual work will be cheaper, about 500 rubles per cylinder. But it is worth remembering that if the case is not conducted by a professional, then mistakes can be made when manually grinding the cylinder head. After a while, you will need to repeat the procedure again.